Twill is not the name of the fabric, but rather the technology of its manufacture. There are many varieties of it - from thin with a printed pattern to durable technical.

The twill has been known for a long time, it was used for sewing clothes for gold diggers and durable comfortable clothes for cowboys. It is believed that best material weaved in the French city of Nimes.

The American Levi Strauss drew attention to her. He called it simply: from Nimes - in French De Nim. This is how jeans, now known to the whole world, appeared.

Let's take a closer look at what it is - twill fabric. Its main feature is the diagonal weaving of warp and weft threads.... This kind of weaving is called twill.

It has many varieties, and each of them gives the qualities necessary for one or another of its applications.

Twill fabric can be cotton, linen, synthetic woolen, silky with a printed pattern... All fabrics are united by a characteristic scar running diagonally, hardly noticeable or well perceptible to the touch. The more prominent the diagonal rib, the thicker and stronger the material.

Manufacturing and GOSTs

In ordinary fabrics, the weave and warp weave remains constant, in twill weft is shifted relative to the warp... The different order of displacement determines its quality and strength. The greater the offset of the weft in relation to the warp, the denser and stronger the material will be. A fabric with a small weft offset is thin with a small rib.

The amount of displacement of the weft threads is determined by a numerical indicator called rappoport... It looks like a fraction, where the numerator is the warp threads and the denominator is the weft threads. If the numerator is larger than the denominator, then the twill is the main one, that is face there will be warp threads. If the numerator is less than the denominator, the front side is weft.

The warp threads are always strong and dense, the weft threads are looser. Threads of different thicknesses are used, so the fabric is different.

In the proposals of manufacturers and sellers, you can often find the designation "GOST", for example "GOST black twill"... This suggests that in its manufacture, the manufacturer was guided by GOST, and not by technical conditions (TU). The state standard regulates quality, safety and strict adherence to technology.

Varieties and description of material

The main varieties, depending on the type of weaving of the twill fabric:

- broken weave, the material is thin and light with a small herringbone pattern;

- complex weaving, diagonal pattern of different widths, the fabric is strong and resilient;

- reinforced weaving, abrasion-resistant fabric with wide diagonals.

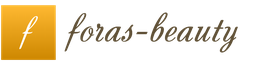

Varieties of weaving twill fabric threads are shown in the photo:

In addition to the main varieties, twill can be shadow, curved, reverse and zigzag. Other classification:

- Harsh... 100% cotton material, very dense.

- Lining... Made from viscose or with its addition, it is characterized by high hygiene compared to synthetic.

- Silk... Smooth fabric with a slight sheen.

- Bleached... This harsh twill, only dyed, is more dense and resilient.

The twill and by dyeing type - plain dyed and printed... Differs in the following characteristics:

- Strength;

- wear resistance;

- durability;

- resistance to getting wet;

- excellent thermoregulation;

- ease of care;

- environmental friendliness;

- color fastness.

In addition, she does not cause allergies, retains its presentation for a long time, does not abrade when worn, passes air well and does not accumulate static electricity, does not roll up, does not absorb odors and does not fade during washing.

Shedding resistance, as well as environmental friendliness are ensured using natural threads and dyes that do not contain harmful impurities. The color fastness is achieved by sulfur dyeing.

Advantages and disadvantages

The main advantage of the twill is its low price and versatility.... Well-colored twill does not fade, so it is used as an upholstery material. Strength and elasticity make it indispensable in sewing clothes and shoes. The ability to accept various impregnations makes the material invulnerable to chemical and oil contamination, as well as waterproof.

The material has no drawbacks.

Application when sewing workwear

Twill is used practically in all areas - household and industrial... Cotton is mainly used for the production of workwear:

- branded;

- work suits for chemical industries;

- and kitchen workers.

For workwear quality such as thermoregulation is important... This means that in cool time it is not cold in it, and in warm time it is not hot. Matters for those working outdoors as well as in hot rooms. Samples of workwear made of twill fabric are shown in the photo:

For military uniform, except for thermoregulation good aeration of the material is important... The material absorbs sweat well, which quickly evaporates from its surface. The skin breathes under the fabric of any density.

Use in other areas

Well colored twill does not fade over time... Combined with its high abrasion resistance, it is ideal for upholstery and curtains.

Severe - used for sewing bags and. The coarsest fabric is used to make lashing belts and abrasive skins. Bleached is used in shoe production.

When added to cotton twill elastane makes an excellent fabric for women's dresses and blouses, keeping their shape well. Lining - used for sewing lining for clothes and hats. It does not lose its shape for a long time, does not tear and therefore prolongs the wear life of the clothes.

Fine Silk Cloth used for the manufacture of the bottom and bed linen ... The wool material is used for tailoring suits, skirts, coats and jackets.

Twill is very popular with famous fashion designers and firmly holds its place on the catwalks around the world.

Twill fabrics are well washed, but for each of them a certain regime must be observed:

- Delicate mode it is necessary for products made of fabric containing wool, silk, and synthetics, the temperature is not higher than 40 degrees;

- Long wash at high temperature (but not higher than 60 degrees) suitable for cotton workwear;

- Medical suits made of thin cotton twill can withstand high temperatures, but not very intense conditions.

The material does not wrinkle, and ironing is not necessary for it. If clothes made of thin silk or viscose fabric still need ironing, do it in the “silk” mode. For cotton and linen, the ironing temperature is 80 degrees.

For twill materials any kind of cleaning is allowed... Grease contamination on the lining fur hat can be removed with a swab moistened with alcohol.

The use of bleaches and chlorine-containing liquids is not recommended... Can not use washing powders containing bleaching granules. But it can be treated with antimicrobial and disinfecting drugs. The ability to wash at high temperatures is due to the twill weave - the product will not shrink.

Considering that twill fabric is very diverse in composition, it is necessary to study the label on the product to establish exactly how to care for it. At proper care the twill will last a long time.

Manufacturer's parameters and average prices

The price tags indicate the parameters in the form abbreviations VO and MVO... VO means water-repellent, MVO - oil-water repellent. The strength indicator is expressed in numbers from 220 to 360 g / m2. The higher the number, the higher the strength.

The price-performance ratio is beyond praise. With high quality, the fabric has a very low price. On average, for its types, the picture is as follows (wholesale prices in 2016):

There are many offers from Chinese manufacturers on the market today that are cutting the price. But the quality of such products leaves much to be desired. By purchasing domestically produced twill, even at a slightly higher price, the consumer still wins.

Twill, thanks to its unique technology and versatility, firmly holds the lead among others the latest materials used for the manufacture of workwear. In addition, she is beautiful and very popular with fashionistas.

Properties and appearance fabrics depend not only on the properties of the raw materials, the method of production and the nature of the finish, but to a large extent on their structure, determined, among other factors, by the type of weaving of the threads.

The weaving of a fabric is a certain order of alternation of overlapping threads of one system with threads of another.

There are a lot of possible types of weaves. Most often they are divided into four groups: main, small-patterned, complex and large-patterned.

The main characteristics of the weave

Weave characteristics include overlap(basic and weft), overlap shift, rapport.

For convenience, the weave is usually depicted on checkered paper, taking vertical rows of cells for warp threads, and horizontal rows for weft threads (Fig. 23, b). The place where the thread of one system overlaps the thread of another system is called overlap. Areas where the warp thread overlaps the weft and extends to the right side of the fabric ( main floor), paint over or mark with a cross. Areas where the weft thread overlaps the warp and comes out to the right side form weft overlap

tiya... Weft floors are not painted over. The weft threads are counted from bottom to top, and the main ones - from left to right. Thus, in Fig. 23, a in the first row, from the bottom, from left to right, the main threads go to the right side of the fabric 1, 3, 5 etc., in the second row - even ( 2, 4, 6 etc.). As you can see, the main overlaps in each next row are shifted by one thread in comparison with the previous one, that is, the shift is equal to one.

ShiftS is a number that shows how many threads the single overlap of this thread is shifted relative to the single overlap of the previous thread. Distinguish between vertical shift S o, showing how many threads are shifted vertically

Rice. 23. Drawing (a) and scheme (b) plain weave

each subsequent overlap (located on the next main thread) in relation to the previous one, and horizontal S at, showing how many threads horizontally each subsequent overlap (located on the next weft thread) is offset in relation to the previous one. For plain weave (Fig. 23, b) S O = S y = 1, for satin weave 5/2 (see fig. 25) S O = 3, S y = 2.

The minimum number of threads that form a complete elementary weave pattern and are equally repeated both along the width of the fabric and along its length is called rapport weave, Distinguish rapports based on R o and duck R at(the number of warp and the number of weft threads involved in the formation of an elementary weave pattern). For all major weaves, rapport R o =R y... In fig. 23, b the weave pattern is highlighted in the lower left corner.

Main weaves. These include linen, twill, satin and satin. In fig. 23 shows a plain weave fabric in which the warp and weft threads overlap one another alternately. As you can see for plain weave R o =R y =2,S O = S y = 1.

Plain weave is widely used in the production of cotton, linen, woolen and silk fabrics for various purposes. In it, each warp thread is intertwined with an adjacent weft thread, as a result of which the fabric has a certain rigidity and, at the same time, greater tensile strength compared to fabrics produced by other weaves from the same yarn in the warp and weft, which have the same density in the warp and weft. In addition, the front and back of the fabric are the same.

In the twill weave, the number of threads in the rapport should be at least three, and the shift S O = S at= 1. It is denoted by a fraction: its numerator shows the number of main overlaps NS O within the rapport, and the denominator is the number of weft overlaps NS at (NS O /NS at). The rapport is equal to the sum of the weft and main overlaps R o = R y = n O +NS at

In fig. 24, a depicts 1/2 twill weave fabric. This weave has R o = R y= 3 = 1 + 2. For 3/1 twill (fig. 24, 6 )R o = R y = 4= 3+1.

The twills are distinguished: weft, on their front side weft overlaps prevail (Fig. 24, a); main with predominant main overlaps (Fig. 24, b); double-sided, that is, having the same number of main and weft overlaps. Fabrics made with twill weaves have characteristic diagonal scars on the front surface, directed from bottom to top from left to right at an angle of 45.

These weaves are used for the production of fabrics: cotton dress and clothing; linseed; woolen dresses, suits and coats; silk dress and lining.

Since the warp and weft threads do not overlap through one, as in plain weave, all other things being equal, the breaking load of twill weave fabrics is lower than

Rice. 24. Twill weave 1/2 (a) and 3/1 (b)

nanny, but the fabric itself is softer, better draped in clothes. To increase the tensile strength, twill weave fabrics are produced with increased density. The fabrics have a smooth surface, which increases the abrasion resistance in the plane. Therefore, lining fabrics are often produced with twill weave.

Satin weave allows you to get a fabric with a smooth, shiny front surface formed by long weft overlaps. Unlike fabrics of plain and twill weaves (Fig. 25), the shift of the overlaps with each next insertion of the weft should be at least two threads ( S 2) . As a result, the main and weft floors are scattered, invisible and form a fairly smooth surface.

Rice. 25. Drawing and weaving pattern of satin 5/2

Satin weave is indicated by a fraction: R/S y R), and the denominator is the horizontal shift of the overlaps S y... For example, satin 5/2 has: R o = R y = 5; NS O = 1;NS at =4;S o = 3; S y = 2 (fig. 25).

In satin weave, as opposed to satin, the front side of the fabric is covered with warp threads. Satin weave as well as satin weave is indicated by a fraction R/S O- the numerator of which proves the number of threads in the rapport ( R), and the denominator is the vertical shift of the overlaps S O... To form a smoother surface and enhance shine, satin and satin weave fabrics are often mercerized or calendered by skipping them at high pressure through the smooth hot rolls of the calender.

Due to the presence of long overlaps, fabrics of twill and satin weave have increased crumbling and spreading.

Small-patterned weaves are divided into two subclasses: derivatives of main weaves and combined ones. Derivatives include reps, matting, reinforced twill (keeper), complex, broken, etc., obtained by modifying the main weaves (linen and twill). The combined ones include diagonal, crepe, waffle, etc., obtained by combining several simple weaves, for example, plain and twill, twill and satin, etc., due to which a small pattern is formed on the surface of the fabric.

By strengthening the overlap of the plain weave, the main and weft reps, matting are obtained (Fig. 26). Reinforced or kiper twill is obtained by reinforcing (lengthening) the main or weft floors. For example, on the basis of 1/2 twill, reinforcing the main overlaps, you can get 2/2, 3/2, etc. (fig. 27, a). Broken twill has a diagonal rib of alternating direction (Fig. 27, b).

Rice. 26. Drawing and pattern of weaving matting

Rice. 27. The scheme of weaving complex twill 411/321 ( a) and broken twill 1/5 ( b)

Examples of combined weaves, obtained by combining 2/2 broken twill and matting, diagonal from complex twill  with wide and narrow stripes are shown in Fig. 27 a, 28.

with wide and narrow stripes are shown in Fig. 27 a, 28.

Rice. 28. The scheme of the combined weave on the basis of broken twill 2/2 and matting

Complex weaves are used when it is necessary to increase the thickness of the fabric, to obtain different front and back sides of the fabric, the pile surface of the fabric, etc.

They are extremely varied. The most common are one-and-a-half-layer, two-layer, multi-layer, pile and openwork.

NS Rice. 29. Drawing of one-and-a-half layer fabric

In two-layer fabrics, one system of warp and weft yarns forms one fabric web, and the other system of warp weft yarns forms another. These two fabrics are joined together due to the connection between the threads of the two systems over the entire surface of the fabric (Fig. 30).

Rice. 30. Section of two-layer fabrics with different links of the canvases:

a) lower base O n over top weft Have v,; b) upper base O v under the bottom weft Have n,; c) using the clamping base O NS

Pile weaves make it possible to obtain on the surface of the fabric a pile formed by the protruding ends of cut threads (split pile) or by loops of threads - loop pile. Depending on what threads (weft or main) the pile consists of, warp or weft-pile fabrics are distinguished.

In fig. 31, a a diagram is given for a fine-pile fabric. Here are the threads of the warp 1, intertwining with weft threads 2 plain weave, form the ground of the fabric. Several threads are inserted between the ground weft threads 3, for example satin weave. After cutting the last threads, a pile forms on the surface of the fabric. 4. To prevent the pile from spilling out, the soil must have a high density, especially along the base.

Weft-pile fabrics include semi-velvet, velveteen-cord, velveteen-rib, etc.

Warp nap fabrics such as velvet, plush, faux fur etc. consist of ground warp and weft yarns and pile warp. These fabrics can be obtained in a variety of ways. For example, on double-leaf machines - velvet. Such fabrics are produced as follows. Each of the two independent root foundations 1 and 2 (fig. 31, b) intertwined with its weft threads 3 and 4, as a result, two root canvases are formed, between which the threads of the pile base are laid in a zigzag manner 5. A special knife, moving between two blades, cuts the threads

Rice. 31. Weft-pile (a) and warp-pile (b) weaves

pile base (along the dotted line). Thus, two webs with a fleecy surface are obtained simultaneously.

Looped (terry) weaves are formed from two systems of warp threads (ground and loop) and one weft. In the process of forming the fabric, the ground warp threads are taut, and the looped ones are loosened. When the weft threads are beaten on the surface of the fabric, they form loops. Terry weaves are used to produce cotton and linen fabrics for bathing sheets, towels, bathrobes, etc.

To develop simplest tissue openwork weave requires ground and leno warp and weft threads. In the process of weaving, the ground warp threads are more stretched, and the leno (openwork) threads are less and are located in the fabric in a wave-like manner, creating an openwork effect.

Openwork weaves produce light and transparent fabrics for dresses, blouses, curtains and other uses.

Large-patterned weaves are called that have a large rapport (more than 24) of differently interwoven warp threads. Such weaves can only be worked out using a jacquard machine, therefore fabrics with large-patterned weaves are sometimes called jacquard.

On jacquard machines, each warp thread is connected with a special device - a hook, which lifts or lowers the thread with a certain pattern determined by the weave pattern. To obtain it, there is a programming device, it is controlled using a special cardboard consisting of separate cards. Each of them has holes cut in a certain order. When the needles interact, connected with the help of special parts with hooks and cardboard, the warp threads are raised or lowered.

The number of cards in the canvas is equal to the number of weft threads participating in the formation of the weave rapport. The more hooks, the more complex pattern you can get it.

Usually silk dress, lining, furniture and decorative fabrics, linen tablecloths, cotton bedspreads, tapestries, carpets and other canvases and piece products are produced by large-patterned weaving.

A fabric is a textile fabric made using a weaving machine using a weaving method. They can be of two types - basic (along the fabric) and weft (weft thread). The arrangement of the threads relative to each other is perpendicular. It is on how they are focused that the appearance of the seamy side and the front side depends. Also, the type of binding of the threads depends on such characteristics of the canvas as strength, thickness, elongation.

Plain bindings

Plain binding can be classified as follows:

- linen;

- twill;

- satin;

- satin.

For a simple binding, the following is characteristic: the main one intersects with the weft only once. For linen binding, alternation of warp and weft threads through one is characteristic. And on the outside of the material, then the main thread, then the weft thread comes out.

Plain cover fabrics are characterized by a flat, matte surface, which is no different from the seamy side or the outside. The canvas has maximum strength and density.

As a result of linen binding, it is possible to obtain the following types of materials:

- madapolam,

- Mayan,

- batiste,

- chintz.

Twill weave fabrics are characterized by the presence of a scar on the outside. It is located from bottom to top and from right to left. On subsequent layouts, the loom moves one thread. The twill binding can be basic and weft. For the first type, it is typical when there are more warp threads on the outside of the material, and for the weft, there are more weft threads. Using twill weave, the following types of materials are obtained: semi-silk, semi-woolen fabrics.

The material obtained by the twill binding method differs from the rest in elasticity. The canvas has low density indicators, as well as increased elasticity along the diagonal.

Satin and satin weaves can be distinguished by their shiny and smooth surface. There are weft threads on the outside of the satin, and the main threads on the front of the satin.

With the help of satin and satin binding, you can get the following fabric options:

- satin (see photo of satin fabric),

- eraser,

- silk,

- corset,

- staple fabrics for pajamas (the link describes the composition of the staple).

The disadvantages of the presented fabrics include flowability and sliding during flooring and sewing.

Small-patterned

this type of binding can be divided into two subgroups: production and combined. The first option is obtained by changing or complicating simple weaves. But the combined ones are materials obtained by the method of alternating and combining simple weaves.

Derived weaves are subdivided into rep and matting. The rep weave is obtained by lengthening the main and weft weaves. Cross reps is when the direction of each main one is observed through 2-3 or more weft threads. In this way, you can get flannel and reps.

The mat is a double or triple weave. It has a symmetrical increase in warp and weft of warp and weft threads. Thus, you can get cotton, silk and woolen fabric. description of twill fabric.

The twill can be broken and reverse. Its essence is that it has a herringbone weave, and the direction of the twill strip changes at an inclination of 90 degrees.

The difference between a reverse twill and a broken twill is that a shift of the twill strip is observed at the fracture site. Use it when receiving fabrics for dresses and coats.

Reinforced satin should be attributed to the derivatives of satin weave. It includes two main overlaps in each horizontal row, which alternate with six weft ones. In this way, you can get the following materials: moleskin, cotton cloth, suede, velveteen.

Complex

The process of forming complex weaves is carried out from 3 or more systems of threads. This category includes:

- double-faced,

- two-layer,

- pile,

- looped,

- leno.

Double-faced- this is the result of the formation of 3 systems of threads, which have a tight weave relative to each other. Thus, satin, bike and cloth are obtained. Two-layer is the result of connecting 4 or 5 systems, interconnected by one of the components of the 4 system or an auxiliary 5 system. In such canvases, the outer and seamy parts can differ significantly. In this case, the outer one will be smoothly dyed, but the seamy one will be multi-colored.  Piqué is a complex weave... Unlike a complex pique, it has an auxiliary thread system. The front surface of the pique is obtained with a linen binding, but thanks to the presence of an auxiliary system, it contracts, forming a convex pattern.

Piqué is a complex weave... Unlike a complex pique, it has an auxiliary thread system. The front surface of the pique is obtained with a linen binding, but thanks to the presence of an auxiliary system, it contracts, forming a convex pattern.

Cloths of pile weaves on the outside are equipped with a split, vertical pile... It is formed from 3 systems of threads: main and 2 root. Can be in linen or twill.

The pile weave can be of two types: terry and primary. Terry is characterized by a pile in the form of loops. Such fabrics are used in the manufacture of bathing towels and certain decorative details.

The primary (openwork) weave is characterized by the presence of transparent cells. Its structure is represented by 3 systems of threads: 2 warp and one weft. Tracery can be distinguished by its high transparency. The fabric is used to obtain cotton, blouse, silk and dress fabrics.

Large-patterned

This weave is formed by combining different simple weaves of weft and warp. But the size and shape of the ornament can be completely different. Large-patterned weaves are divided into two types: simple and complex.

A certain type of fabric is called twill, but it would be more correct to call this a whole group of fabrics with a characteristic way of weaving threads. The twill type is included in the basic group and is the second most common after the linen one.

Such fabrics are universal: they are woven from almost any raw material and are used for sewing many types of products. The main distinctive feature twill - a pattern of diagonal lines, which is formed due to the frequent displacement of the overlap of the warp and weft threads.

Appearance

The twill weave of the fabric has one recognizable feature - it is a diagonal pattern of parallel stripes. Sometimes this method of creating canvases is called diagonal or marque. The scar stretches along the width of the canvas from left to right upward, less often vice versa. The pattern is formed due to the constant displacement of the weft threads relative to the warp. This is how the characteristic diagonal relief is obtained. This scheme contains the main difference between twill and plain weave, in which everything is built according to the chess principle.

Twill canvases come with both a smooth and a small-patterned seamy side. Fabrics are produced, printed, bleached twill is also found. A combination of threads of two colors is possible, as, for example, in.

Weave varieties

The variety of thread patterns is determined by the varieties of twill weave threads:

- Classic type. The angle of the scar to the right side, the lines are the same in width.

- Reverse - the tilt of the scar to the left.

- Complex variety - several relief stripes of different widths are distinguishable. The strength and other properties of the canvas do not change from this.

- The broken mesh allows you to make a drawing from different directions corners. This is the herringbone pattern. In a broken way, fabrics are mainly woven from wool, cashmere, less often cotton fibers.

- Reinforced braiding allows for wide diagonals.

Tissues differ in the acuteness of the scar angle. If the warp and weft threads are equal, a standard 45 degree angle is obtained. When the base exceeds, the angle will be wider, and vice versa when more basics, the angle is sharper. The twill effect also depends on the properties of the yarn itself. If it is thick and twisted, the pattern comes out more embossed, and the matter is coarser.

What is good about twill

The spread of twill weave is explained by a number of positive properties of materials. Any fabric woven in this way, regardless of the raw material, has a number of advantages:

- It has the highest strength and tear resistance.

- It is not covered with pills and will last a long time due to its wear resistance.

- It is practically indestructible matter.

- Accepts various reinforcing impregnations well: water-repellent and others. This is an excellent property for fabrics used to make workwear.

- The fabric is softer and smoother than plain weave.

- Hygroscopicity - the ability to absorb and release moisture - is also inherent in twill.

- The canvas stretches slightly diagonally, it is quite elastic, does not hinder movement when worn.

- Bilateral fabrics are pleasant to the touch, it is comfortable to be in such clothes.

- The twill drapes perfectly.

- Easy to clean: easy to wash and dry quickly.

- Fabrics on a natural basis are environmentally friendly, hypoallergenic.

- Does not have the property of electrifying.

- It has excellent thermoregulation: it retains heat, but allows air to pass through, and provides the necessary comfort.

- The twill is affordable and comes with a large selection of small patterns and fabric colors.

Advice! Due to the slight stretching, care is required when cutting the product so that it does not warp.

Review of Matter

The threads used for twill weaving have an equal effect on the properties of the finished fabric. The versatility of twill lies in the use of both natural fibers - cotton, linen, and artificial and synthetic.

Usually these are very dense and warm materials. Wool of twill weaving is used for sewing warm winter and outerwear.

Examples:

- Gabardine- Merino wool fabric. Jackets, coats, suits are sewn from it. In the furniture industry, gabardine is used as an upholstery material. Such furniture looks elegant. The peculiarity is a 60-degree inclination of the rib on the front side and a smooth reverse side.

- - woolen fabric for sewing warm clothes, elegant suits, coats, hats, bags. Made from sheep wool... Properties of tweed: retains heat, does not wrinkle, has an aesthetic appearance.

Wool blend

For twill weave, blends of fibers are used. Half-woolen fabrics have proven themselves well. For the base, cotton thread is used, woolen fibers act as a weft.

Wool blend twill is good for sewing clothes. A popular variety is plaid: fabric with a pattern in a large check.

Cotton

100% cotton fabrics are the densest. This twill is called harsh.

One of the most widely used and beautiful fabrics with a twill pattern is denim, better known as jeans. Dyed threads are used for the twill warp, unpainted for the weft.

The upholstery of mattresses is also sewn from cotton twill. Upholstered furniture is covered with such fabrics. Cotton is also widely used for sewing home textiles.

Coarse 100% cotton fabrics are used to make work clothes, trousers for miners, fastening belts, bags, mittens and other household accessories.

Artificial and synthetic fibers to improve its elastic properties. Typically, the proportion of cotton in blended fabrics is at least 70%. So, fabric with the addition of elastane is called stretch. Women's clothing is sewn from it.

Silk and semi-silk

Silk twill fabrics are soft and pleasant to the body bed sets... For semi-silk fabrics, a silk warp and cotton weft are used.

Viscose

Viscose yarn is extracted from cellulose. Thin viscose twill weave fabrics are widely used for lining outerwear and hats. Many elements of women's wardrobe are sewn from fabric.

How to care for products

Despite the strength of this weave, you should be more careful with textiles. Care rules depend on the composition of the fabric. If it contains wool, cashmere or silk fibers, then washing, drying and ironing are carried out strictly according to the recommendations on the tag. So, the temperature should not exceed 40 degrees, chlorine-containing substances, bleaches, spinning at high speeds are prohibited.

In other cases, washing is allowed at a temperature not exceeding 60 degrees at medium speed. The twill does not shrink; in extreme cases, it shrinks a little after the first wash. Only the coarsest and toughest fabrics can be wrung out at maximum speed and exposed to high temperatures... Since the fabric is practically not wrinkled, it can be easily ironed with a warm iron from the wrong side.

There is no person who has not come across a twill group of fabrics in life. Such canvases are used very widely. It is difficult to imagine a modern wardrobe without jackets and denim pants. The workwear also turns out to be strong and durable. Regardless of the raw material, twill is a comfortable and practical material.